Today, the world uses almost twice as much of the earth’s resources than it can regenerate. In a recent article from World Economic Forum, by 2030 — with a projected 8.5 billion people — the global demand is expected to increase 35% for food, 40% for water, and 50% for energy. Without a solution to reverse this trend, we could see many repercussions — energy shortages, air pollution, destruction of ocean life, severe weather events, and more.

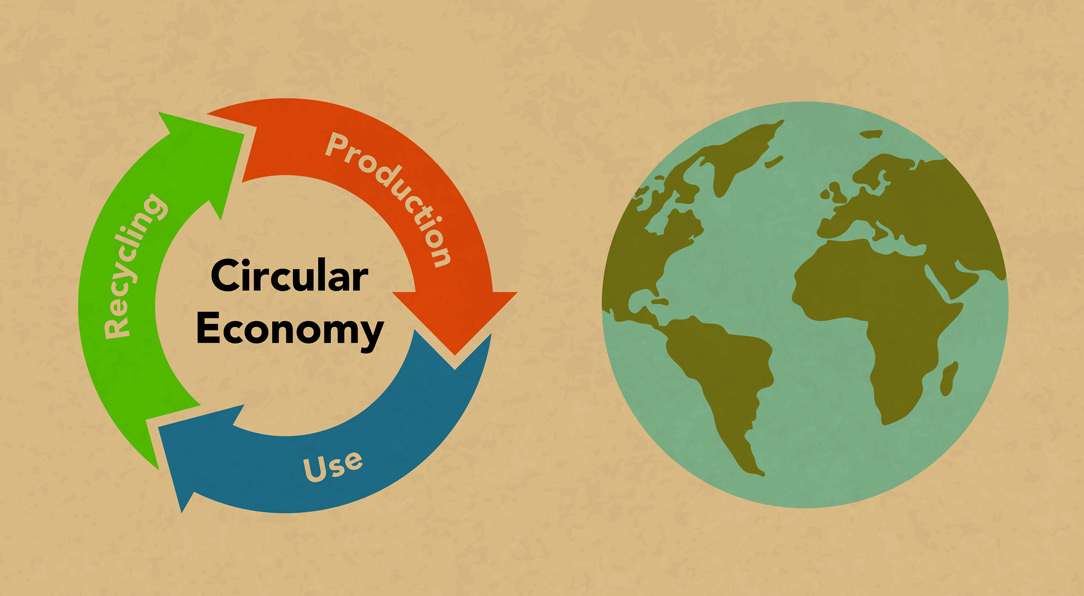

To avoid this destructive outcome, we must shift our focus to the need for a circular economy — a way of building an economic system that eliminates waste and is focused on the continual use of resources. Our society has become very familiar — and quite frankly, too comfortable — with the traditional linear economy of make, use, and dispose. In our minds, when something comes to the end of its life, we naturally throw it away. With today’s advances in science and technology, it is possible to consume without exhausting our planet’s resources and causing harm to our environment. Our innovative society can fully shift to the idea of designing without having waste in mind, but rather designing with reuse in mind. Examples of this would be the reusable water bottle and reusable grocery bags. An even more complex example is Johnston Controls who has designed a battery that is 99% recyclable, which is amazing considering how toxic the product is.

When we shift our focus to a circular economy, our world will reap many benefits: improved health, reducing the pressure on our environment, business growth and new employment opportunities, and many more. This is imperative to create a better world for future generations.

When we shift our focus to a circular economy, our world will reap many benefits: improved health, reducing the pressure on our environment, business growth and new employment opportunities, and many more. This is imperative to create a better world for future generations.

Here at SpectraTurf, we are proud to do our part in contributing to a circular economy through our innovative upcycling process. In 2019, we started developing a new process of removing old safety surfacing that was already repurposed from tires, and upcycling it for new safety surfacing material. As a result, we are no longer sending any old surfacing to the landfills. Read more about our upcycling process in this recent blog.